Specialists in high-volume printing.

Severotisk is one of the most dynamically growing printing companies on the Czech market.

We can rely on three rotary printing presses in our production which give us great flexibility in the processing of orders. Our printing machines are equipped with additional technologies for the optimum balance of color, paper quality and precise management of other technical parameters.

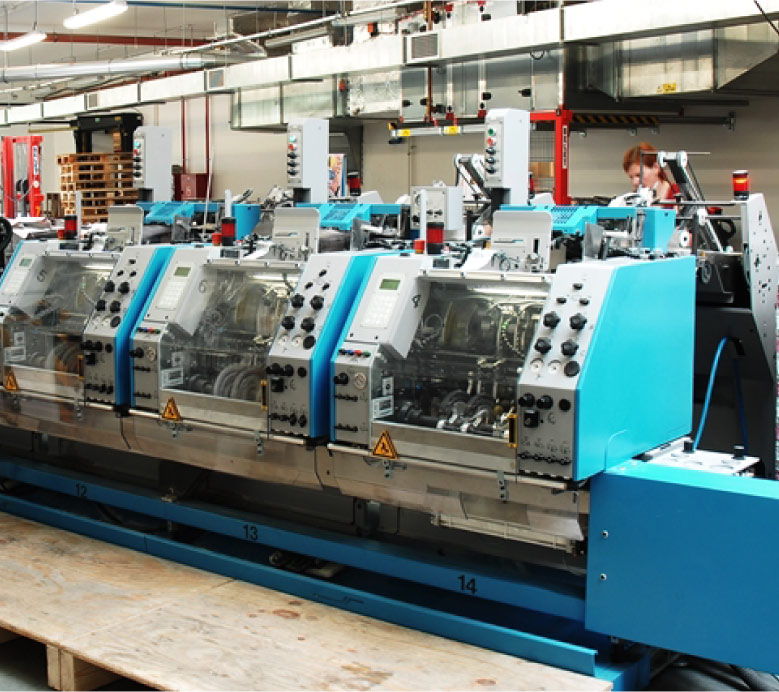

Stitch binding

more

Stitch binding or saddle stitching is the standard form of binding in magazine production. The printed pages are put together and stapled with wire staples.

Additional technologies

more

We provide product finishing work according to the individual requirements of our customers, be it inserting, product wrapping, numbering, barcoding, personalization, address labeling etc. In the post-processing, modern technology and handwork are combined to perfect the product.

Prepress

more

We accept data in Portable Document Format (PDF) or PostScript (PS) formats on standard data carriers (CD-R / RW, DVD ± R / RW, USB flash) or via our FTP server. We then process the data in our studio and prepare it for printing and bookbinding. To approve the print color scheme, we use the modern SoftProof color management system.

Postpress

more

Finishing is carried out in our bookbinding and finishing departments, where both handwork and BUHRS automated systems are used to create the final product.

Warehousing and Logistics

more

We provide product delivery to locations designated by the customer across the Czech Republic and both the EU and non-EU countries. The expedition center is equipped with a CYKLOP strapping machine.

Comprehensive technology

State-of-the-art machinery

PRINTING PRESSES

L2 / 1997 / Lithoman III 32 / Gämmerler / no robot

Offset rotary press with drying

• manufactured by MAN ROLAND

• color scheme 4/4 Euroskala

• web max. format 904 × 1260 mm (cylinder circumference × maximum width)

• signature 226 x 315 mm

• CONTIWEB Ecotherm dryer

• printing speed approx. 50,000 rph

• Q.I. PRESS web offset printing control system

• Manroland Intelligent Density Control (IDC)

• SoftProof

Complete In-line PostPress solution.

L3 / 2006 / Lithoman III 48S / Gämmerler / Inlog + ABB

Offset rotary press with drying

• manufactured by manroland Goss

• color scheme 4/4 Euroskala

• web max. format 890 × 2060 mm (cylinder circumference × maximum width)

• signature gross 222.5 x 330 mm

• ECOCOOL CONTIWEB drying tunnel

• max. print speed 65 000 rph

• ICC, ICC-D, IRC, IDC + COLOR CONTROL automatic machine control systems

• CONTIWEB CFA remoistening and silicone applicator systems

Complete In-line PostPress solution.

L4 / 2018 / Lithoman III 48S / Inlog / Inlog + ABB

Offset rotary press with drying

• manufactured by manroland Goss

• color scheme 4/4 Euroskala

• web max. format 900 × 1905 mm (cylinder circumference × maximum width)

• signature 226 x 318 mm

• CONTIWEB drying tunnel

• print speed approx. 55,000 rph

• Q.I. PRESS web offset printing control system

• manroland Intelligent Density Control (IDC)

• SoftProof

BINDERY

Ferag wire-stitchers / saddlestitchers:

Unidrum UDR-2-350/2010

6 horizontal collating stations

minimum book size 190 × 148 mm

maximum book size 480 × 340 mm

rear cross - fold 8 – 15 mm

front cross-fold 8 – 15 mm

mechanical speed 15 000 – 30 000 cycles per hour

flatbed folding machine

UCV40 2014

1 inserting lines for cards and other inserts

stitching with 1-3 stapes and 0,6 mm wire

MüllerMartini wire-stitchers / saddlestitchers:

Tempo 22 / 2008

7 horizontal collating stations

minimum book size 200 × 115 mm

maximum book size 340 × 280 mm

rear cross-fold 6 - 15 mm

front cross-fold 8 - 15 mm

mechanical speed 6 000 - 22 000 cycles per hour

flatbed folding machine

2 inserting lines for cards and other inserts

Biliner MMAP self-feeder for up to four tip-in plates / attachments

stitching with 1-4 staples and 0.5 mm - 0.6 mm wire

UV InkJet Buskro technology:

Buskro Atom print head

UV techn., resolution up to 600 DPI

monochrome schwarz

online customisation of bindings

processing of customer databases (optimization by our specialists)

printing of addresses, images, EAN, QR codes

processing speed 8 000 pcs/hr.

CTP

Two Kodak Magnus VLF Platesetter ( max. plate format 2083x1296 mm) CTP units with Kodak Mercury T-HD 1550 and Kodak T-HDX 1250 developing machines for high-quality thermal imaging.

CMYK to CMYK conversion

stochastic screen (Fogra 43)

including ISO 12647-2:2014 (Fogra 51)

certified digital GMG proofs:

Prague

Epson 4900 A2+ format (internal spectrophotometer)

Teplice

Epson 4880 A2+ format

Preparation of printing plates:

Prague

2x KODAK platesetter VLF format:

Magnus VLF 6383

Magnus VLF 5570

SquareSpot technology

Teplice

platesetter VLF format:

Luscher Xpose 180

Digital Printing:

Konica Minolta bizhub PRESS C8000e

SRA3+ format

V1 finisher

60-350 gsm, lamination possible

DTP:

We work on the PC platform

break, editing video materials, client data processing

SW: Adobe InDesign, Photoshop, Illustrator

flatbed scanner Epson Expression 10000XL A3+ format

production of own calendars for diaries

OTHER EQUIPMENT

OTHER EQUIPMENT

Buhrs 4000

• 4x longitudinal feeder

• 1 transverse feeder

• 1 x glue application unit

• 1 x 3D insert loader

• 1 wrapping unit

• 1 labeling unit

• 1 stacker

Processing speed 3,000 - 12,000 pcs per hour depending on the type of processing

OTHER EQUIPMENT

Schneider Ozga UB01-3 / 4 wrapping machine

OTHER EQUIPMENT

Cyklop strapping and packaging line, equipped with a fully automatic strap (heat) sealer and pallet wrapper

OTHER EQUIPMENT

Kallfass, Super Wrap shrink wrapping machine - shrink tunnel

Finishing

Manual processing

deposit on position

pasting 3D object on title

pasting a point inside the magazine

assembling magazines into a bag

EAN code overlay

folders unfolding